What is Supply Base Management?- Definition

Before going into detail about supply base management, it’s important to first define what a supply base is. A supply base is a component of the overall supply network that is largely controlled by the customer. The buyer then uses contracts and various purchase agreements to manage the vendors in this supply base. We can better grasp the meaning of supply base management if we understand what a supply base is.

SBM (supply base management) is the process of managing your whole supply chain, which includes your immediate (current) suppliers, minor suppliers, and any future vendors. One of SBM’s goals is to help procurement teams manage vendor risk, behavior, and information. Another objective of SBM is to assess vendor relationships and identify pathways that encourage improved supply chain management. Chief procurement officers and their teams can use this procurement technique to manage lean and effective operations.

Supply Base Management – Best Practices

The procurement industry evolves on a daily basis. Because of increased automation, product lifecycles are significantly shorter, and markets are not as predictable as they once were. As a result, staying relevant is critical. As a result, CPOs must concentrate on implementing the best supply base management practices.

1. Supplier Identification

Supplier identification is the first port of contact for any procurement team when it comes to supplier base management. Businesses are seeking excellent vendors, not just any suppliers. The proper vendor can help the organization source at the lowest possible cost. Collaboration with the proper supplier provides the buyer with access to new markets, which can assist to keep procurement costs low.

2. Supplier Information Management

Every day, large and medium-sized businesses must deal with a wide range of procurement requirements. As a result, it is vital to have an efficient system for gathering, organizing, and preserving supplier information. Buyers expose themselves to risk in the supply chain if effective supplier information management is not in place. The importance of visibility cannot be taken for granted.

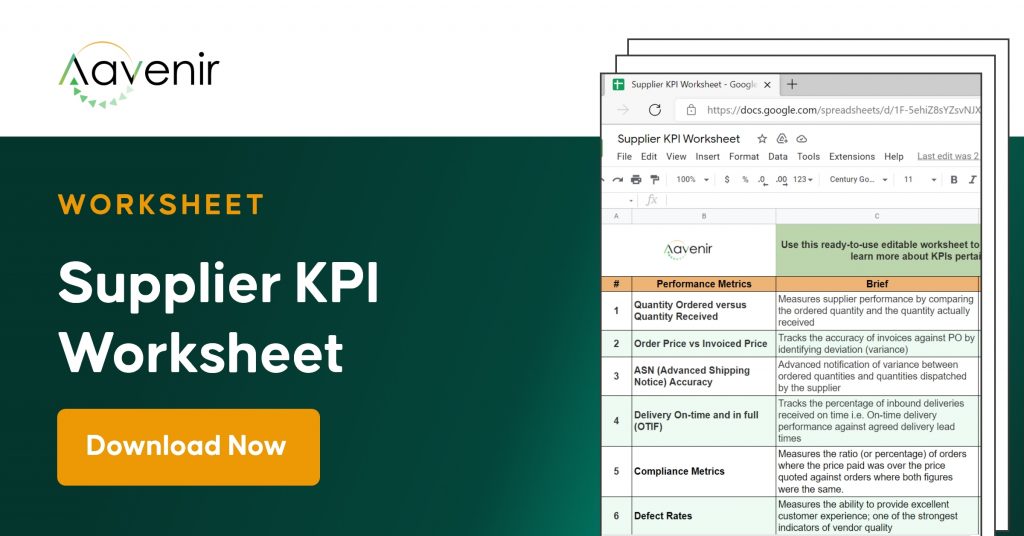

3. Supplier Performance Management

How can you know if your suppliers are adding value and adhering to the terms and conditions that were agreed upon? How can the effectiveness of suppliers be measured?

Supplier performance is routinely monitored so that businesses may benchmark, grade, and rate each vendor. This enables businesses to keep working with suppliers who provide them with the essential value.

Explore Additional Resources To Know More