Indirect spend can be a noteworthy untapped opportunity for retailers looking to save money and redirect funds for growth investments. Retailers face significant profit margin pressures. They aim to deliver goods and services to customers on time and at competitive prices, battling prevailing inflation and supply chain challenges. So, along with direct spend, indirect spend also needs to be managed and optimized for better profit margins.

Traditionally, spend management in the retail industry has focused on optimizing direct spend, as it is directly tied to procurement of raw materials, components, finished goods, and services necessary for the production of retail goods. Procurement teams manage direct spend effectively as an essential part of keeping costs low, generating value, and supporting the retail organization’s profitability and competitive strength, but today the most relevant question for the retailers is:

Does my team have visibility into all indirect spend? Are indirect expenses getting out of control? What is the impact of uncontrolled indirect spend? How can I gain better control and governance on indirect spend?

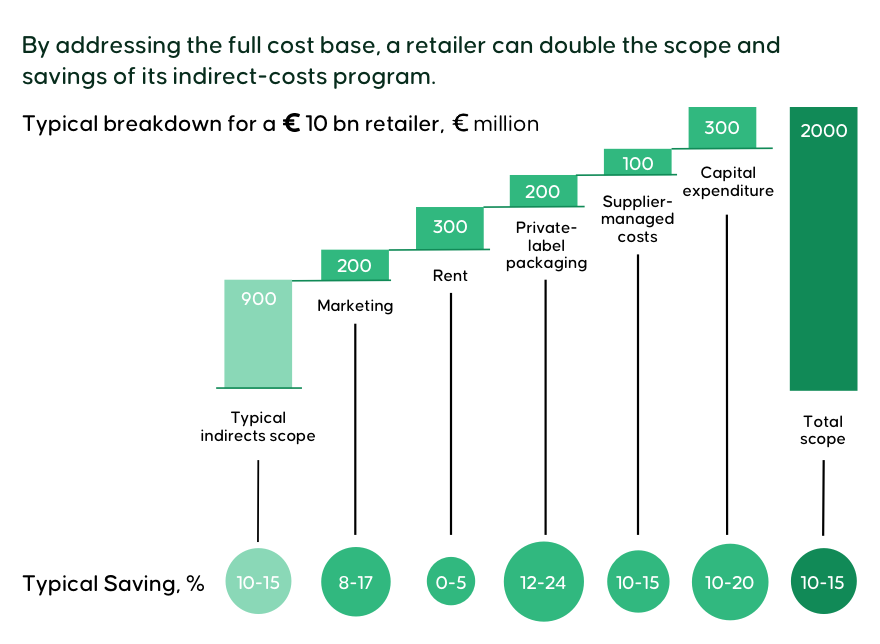

According to McKinsey, indirect costs account for an average of 10-15% of sales for the retail industry.

The good news is that most retailers are aware that their indirect spending is far from optimized, and are aware of the key challenges related to indirect spend in procurement:

- lack of spend visibility

- fragmented ownership

- spend authority

- an absence of incentives to reduce indirect spend

- a siloed approach to the procurement of not-for-resale (NFR) categories

Approaches to Optimize Indirect Procurement Spend in Retail

Visionary retailers are exploring new approaches to manage indirect spend—and achieving results! These retailers aren’t viewing indirect costs as a concern only for the procurement function. Instead, they’re looking to transform indirect spending across the entire business. They’re overcoming challenges by leveraging new operating models and tools, such as:

1. Cross-functional team approach

Transformation of indirect spending requires the involvement and commitment of more than just the procurement staff. A cross-functional team approach breaks down silos, surfaces questions about the retail business needs, and helps make balanced trade-offs.

A cross-functional team approach pulls the critical supplier-management functional levels (such as competitive bids and supplier consolidation) that affect who the retailer buys from and at what price. The unit also pulls process-management levels, which influence how a retailer buys. If the various functions comply with procurement policies and use only preferred vendors, it will reduce maverick spending, help improve and centralize spend visibility, and equip the retailer to negotiate better pricing and fees, and vendor payment terms.

Business Case: A retailer seeking to optimize logistics spending, tasked a cross-functional team with redesigning its distribution network. The team was able to reduce end-to-end costs by selectively increasing specific logistics costs. For example, it switched some deliveries from sea to air to gain sales and reduce markdowns. It also increased delivery frequency for some products and stores while decreasing it for others.

2. Focused and stronger supplier collaboration

Retailers should work with suppliers on cost improvements and innovations. Suppliers are excellent idea generators because they are more familiar with a retailer’s negative behaviors than the retailer is, and they can assist in changing those behavior patterns rather than losing the business. Retailers also invest in improving supplier capabilities in ways that will pay the investment back several times over. With a strong supplier relationship, the retailers can benefit from better product quality and availability, faster responses to market needs, less administrative effort, greater efficiency, and lower total cost.

The elements of successful supplier collaboration include

- focusing on a limited number of suppliers to deliver the highest return on investment

- establishing a robust value-sharing agreement at the outset

- creating a dedicated supplier-collaboration team separate from but aligned with category managers

- building disciplined performance management and benefits-tracking processes and systems

Business Case: When retendering its contracts for outsourced warehousing, one retailer required suppliers to submit proposals for improving the joint warehousing operation. Based partly on these proposals, the retailer reduced its supplier count to two, allowing for closer collaboration while maintaining some competitive tension.

3. Automating Source-To-Pay with AI-enabled tools

Digitization has revolutionized every business process and will continue to do so; sourcing is no exception. Today, leading retailers are using digital and analytical tools in the following areas to achieve dramatic reductions in indirect costs:

- Spend visibility: Advanced digital solutions, powered by artificial intelligence (AI) and machine learning, enable retailers to rapidly and accurately map the relevant spend base into granular categories, highlighting who spends how much on what. Cutting-edge digital procurement solutions can pull purchase-order (PO) and invoice data from multiple systems to create a “spend cube,” automatically generating benchmarks on pricing and specs, as well as dashboards and reports to help category managers monitor spending.

- Spend control: Digital procure-to-pay tools give retailers better spend management by enforcing more discipline in how suppliers are set up and approved and supporting a more rigorous PO-approval process.

Aavenir smart solutions are designed from the ground up, to help you achieve that competitive advantage, helping you know your indirect spends. With Aavenir’s contract lifecycle management solution, you can negotiate better terms with your indirect spend suppliers, such as payment terms, quality specifications, return policies, defect rates, and more. Not just that, Aavenir Invoice Automation solution will also help you track any deviations and non-compliances from the agreed terms so you can quickly catch items or services that were delivered to you at prices different from the contracted price or if you are being charged higher.

Business Case: A retailer reduced the cost of its paper shopping bags by 25% by redesigning them. Through digital analysis of basket size, product dimensions, and data from cashier surveys, the retailer determined the ideal measurements of a shopping bag based on the distribution of physical volume and weight of products.

Manage indirect spend for a direct impact on your company’s health

Indirect spending has moved from the shadows of procurement and into the limelight of value creation. With a simple change in the outlook on indirect spending, many organizations in the CPG and retail industries can learn from other industries to realize substantial savings:

- Delta Airlines could save $11 million on hotel bookings in one quarter by employing a software solution that revealed financial issues.

- World-famous motorcycle brand Harley-Davidson saved $4 million by outsourcing all indirect spend to just three suppliers.

- Cadence design systems reported $6 million in savings by investing in a technology that provided insights and cost-saving opportunities.

In conclusion, organizations can eliminate waste and inefficiencies by investing in the right technology solution and adopting well-researched best practices for managing indirect spend as part of the overall procurement strategy. By increasing focus on indirect spend, the procurement function could transform into a source of significant cost savings helping achieve a greater competitive advantage, and thus a healthier bottom line for the organization.

Source: McKinsey