What is Supplier Sourcing?

Looking out for suppliers is a critical task faced by procurement professionals. The main goal is to meet the right supplier at the right time and place. There are several key factors that determine the selection of suppliers. Some of them are price or affordability, location, reliability as reliable suppliers will deliver required material efficiently and, most notably, stability. The suitable suppliers provide the most appropriate products or/and services to meet the business needs.

Understanding Supplier Sourcing

Searching for suppliers is a critical step in the procurement process. The suppliers need to meet the company’s expectations regarding cost, quality, deadline, and performance. In addition to this traditional outlook, companies now face co-development and innovation challenges. Strategic sourcing encompasses all these realities and becomes a sustainable competitive advantage.

Simply put, sourcing is the process of selecting suppliers to provide the goods and services you need to run your business. It may sound uncomplicated, but the process can be complex.

Supplier Sourcing involves the following:

- Finding quality sources of goods and services

- Negotiating contracts

- Establishing payment terms

- Market research

- Testing for quality

- Considering outsourcing for goods

- Establishing standards

Supplier Sourcing – Features

To develop suppliers, It’s essential to manage them effectively by:

- Continuous evaluation

- Faster product development

- Managing and mitigating supply risks

- Increased supplier engagement

- Manage quality initiatives

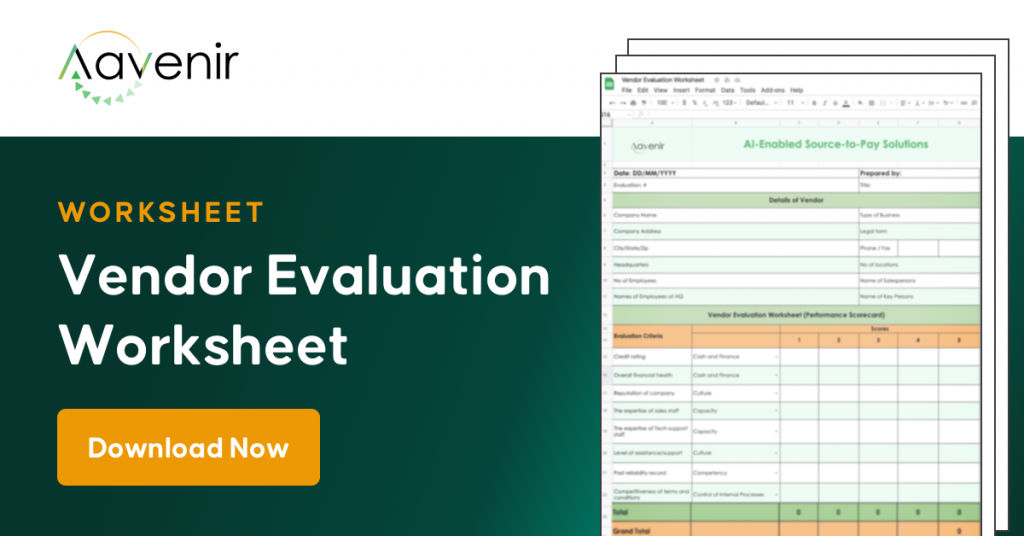

Suppliers Evaluation

These services are provided to serve customers, continuously working with their procurement team to monitor suppliers on critical factors- Quality, Delivery, and delivering improvement plans as per the organization’s need.

Product / Commodity Inspection Services

Provide customers with a capable supplier that ensures material delivery per agreed quality, quantity, packing, and schedule.

- Identifying the right supplier is one thing; the other is to train and develop the supplier, get the right parts, and establish a reliable production process.

Supplier Identification

- Identify the products or services that can be successfully sourced globally. In developing a “roadmap for success,” determine the success metrics, conduct an initial business assessment of potential suppliers or partners, and recommend the most suitable supplier.

After completing supplier development services, the managers can provide product containment services until you are confident of a supplier’s quality.

- Help in developing or improving an effective business-driven sourcing strategy.

- Evaluation and selection of suitable suppliers and service delivery models.

- Assess and develop effective governance and relationship management.

- Assessing and negotiating high-performing contracts.

- Measure progress and adapt to change.

- Benchmark current data to current industry standards to maximize value return.

Explore Additional Resources to Know More

Frequently Asked Questions about Supplier Sourcing

Q: How do I find potential suppliers?

A: You can find potential suppliers through market research, trade shows, online directories, referrals, and industry networks.

Q: What factors should I consider when evaluating suppliers?

A: Consider factors such as quality, price, reliability, capacity, financial stability, and compliance with ethical standards.

Q: How can I negotiate with suppliers effectively?

A: Prepare well, clearly define your requirements, understand their constraints, and aim for mutually beneficial solutions.

Q: How often should I review my supplier base?

A: Regularly review your supplier base to ensure ongoing performance and competitiveness.

« Back to Glossary Index